HTC

Superfloor™

HTC

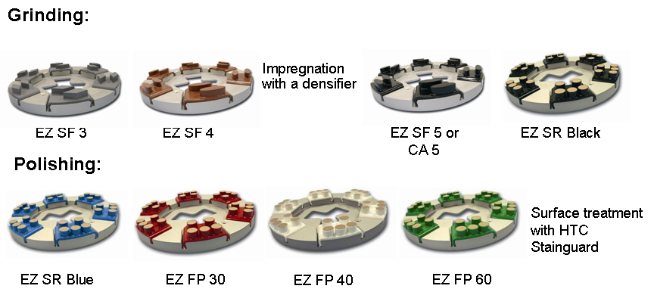

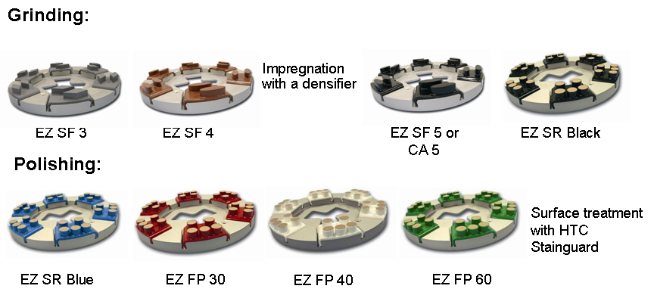

Superfloor™ utilizes

an innovative grinding and polishing system

which includes both metal bond and resin

bond diamonds to bring out the natural beauty

in your concrete floors. HTC Superfloor™ produces

a highly reflective surface finish that is

not only aesthetically pleasing, but reduces

maintenance costs and increases durability. HTC

Superfloor™ utilizes

an innovative grinding and polishing system

which includes both metal bond and resin

bond diamonds to bring out the natural beauty

in your concrete floors. HTC Superfloor™ produces

a highly reflective surface finish that is

not only aesthetically pleasing, but reduces

maintenance costs and increases durability.

What Makes HTC Superfloor™ the Best?

Functional

- Dense, polished surface helps protect

against absorption of oil and other contaminants.

- Resists tire marks from fork trucks and

other traffic

- Harder and stronger than other floor

finishes

- 40% more abrasion resistant than unfinished

concrete

- 20% increase in impact resistance than

unfinished concrete

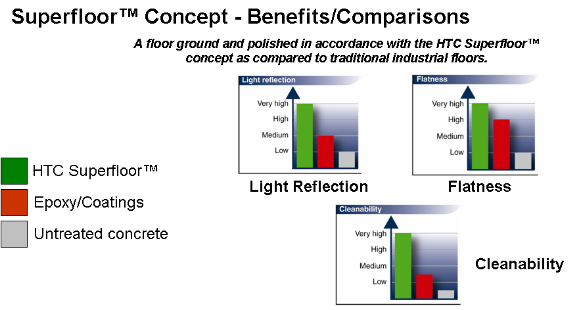

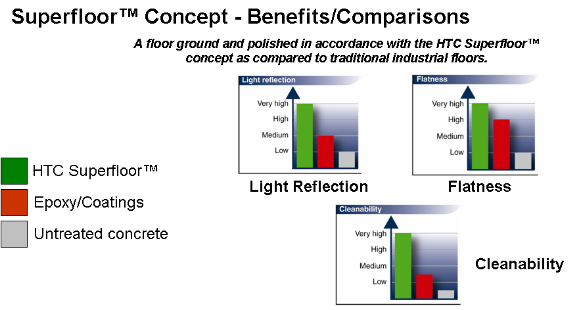

- 30% increase in ambient light reflection

from unfinished concrete

- Flatter, more level surface

- OSHA

recommends that you achieve a static

coefficient of friction (SCOF) of 0.5

for polished surfaces- HTC Superfloor™ SCOF

wet: .50 / dry: .58

- Easily

add color to existing concrete during

the HTC Superfloor™ process.

Ecological

- Dry, dust-free grind filters out 99.9%

of all airborne dust

- No

VOC’s

- No coating, urethane, waxes or topical

coatings applied

- No slurry

- No protective gear such as ear plugs,

masks, or retardant proof clothing necessary.

- New water-based dyes for environmentally

friendly coloring.

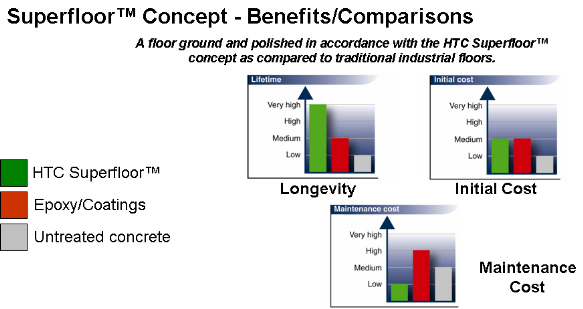

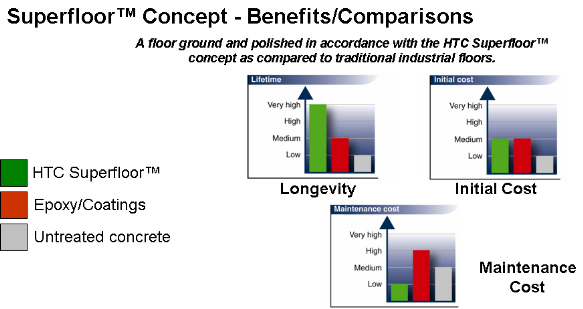

Economical

- Lower initial costs compared to most

other floor coverings

- No down time waiting on chemical processes

to cure

- One-time application with minimal maintenance

- Lower maintenance costs with less wear

on cleaning equipment and consumables

- Long life cycle of 5-10 years

Simple cleaning and maintenance, done correctly,

are all that's required for a long-lasting

HTC Superfloor™. Due to its

resistance to tire marks and other contaminants,

the floor only needs a light cleaning from

time to time. and a light polishing every

three years. HTC Superfloor™ never

requires harsh chemicals to clean or strip

the surface like some other processes -

and over a 20-year period, Superfloor™ costs

a fraction of what vinyl, tile or coatings

cost to maintain. Every day, sweep

the floor with a dust mop or fine bristle

broom to remove surface debris such as

sand and dirt.

Cleaning

and Maintaining a Superfloor™

- Remove Debris -Areas

must be cleaned daily using either a dust

mop or fine bristle broom to remove sand

and debris that may scratch the surface.

- Use

CLEANER -Clean

the polished concrete surface with a mop

or autoscrubber (make sure that the equipment

is in good working order). If using

autoscrubber, combine with TWISTER™ for

maximum results and aesthetics.

- Restore -After

extensive traffic and/or poor maintenance

procedures, your polished concrete may

lose some of its luster. The best

way to restore it is to follow the TWISTER™ Cleaning

Program. If the floor was too poorly

maintained and is rough and pitted, re-polish

the floor with diamond tooling.

- Protect- For

added protection, apply HTC Stainguard™. Apply

a very thin coat with a wax applicator

or with an airless pump sprayer.

|

HTC

Superfloor™ utilizes

an innovative grinding and polishing system

which includes both metal bond and resin

bond diamonds to bring out the natural beauty

in your concrete floors. HTC Superfloor™ produces

a highly reflective surface finish that is

not only aesthetically pleasing, but reduces

maintenance costs and increases durability.

HTC

Superfloor™ utilizes

an innovative grinding and polishing system

which includes both metal bond and resin

bond diamonds to bring out the natural beauty

in your concrete floors. HTC Superfloor™ produces

a highly reflective surface finish that is

not only aesthetically pleasing, but reduces

maintenance costs and increases durability.